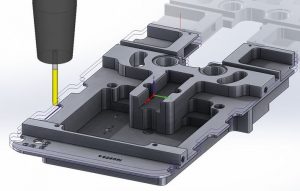

The code for a 2.5D machining is significantly less than 3D contour machining, and the software and hardware requirements are (traditionally) less expensive. A typical example involves an XY table that positions for each hole center, where the spindle (Z-axis) then completes a fixed cycle for drilling by plunging and retracting axially. Ģ.5D objects are often greatly preferred for machining, as it is easy to generate G-code for them in an efficient, often close to optimal fashion, while optimal cutting tool paths for true 3-dimensional objects can be NP-complete (nondeterministic polynomial time complete), although many algorithms exist.Ģ.5D objects can be machined on a 3-axis milling machine, and do not require any of the features of a higher-axis machine to produce.Ī 2.5D machine, also called a two-and-a-half-axis mill, possesses the capability to translate in all three axes but can perform the cutting operation only in two of the three axes at a time due to hardware or software limitations, or a machine that has a solenoid instead of a true, linear Z axis.

Objects of this type are often represented as a contour map that gives the height ( i.e., thickness or depth) of the object at each point. In machining, 2.5D refers to a surface which is a projection of a plane into 3rd dimension – although the object is 3-dimensional, there are no overhanging elements possible.

0 kommentar(er)

0 kommentar(er)